With the continuous development of industrial science and technology, the manufacturing industry, as a pillar industry of the country, is constantly transforming and developing in the direction of 4.0. From "Made in China" to "Created in China", China's industrial strength can no longer be underestimated. Even the processing, testing, and assembly of the downstream industries are gradually being replaced by automated loading and unloading, rather than having workers perform mechanical labor. Our company has independently developed this intelligent detection system for concrete compressive strength based on years of industry experience, understanding of products, and analysis of customer needs. In order to increase the detection speed of building concrete blocks and reduce errors caused by workers' operations, the intelligent detection system for concrete compressive strength is designed to solve the above problems. This system can automatically identify the concrete test block number, automatically measure the size and angle, automatically perform compression tests, automatically upload data to the network platform, distinguish between qualified and unqualified samples, recover samples after the test, and alarm for abnormal operation of the entire system.

System Features

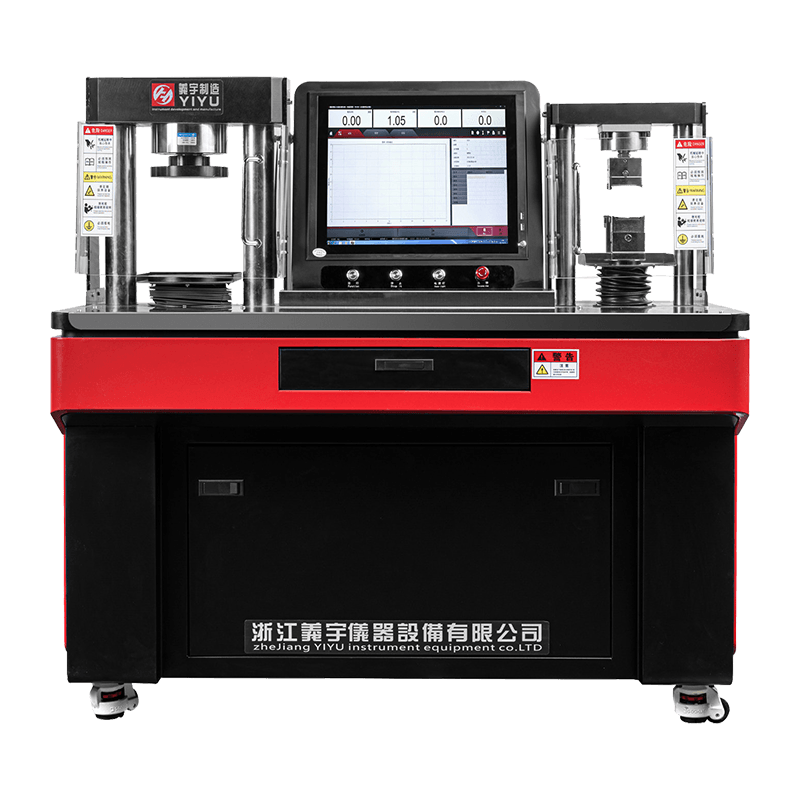

◆ Structure: Robotic arm linked to two presses.

◆ Robotic arm payload capacity: 20kg

◆ Automatic software upgrades, automatically updating to the latest version when connected to the internet.

◆ Enables data collection and control of the pressure testing machine, automatically switching the press loading rate to meet the required setting based on the sample strength grade confirmed by code scanning.

◆ Enables control of the loading and unloading systems.

◆ In special circumstances, any actuator can be operated in manual mode.

◆ Features a fault alarm function, dynamically displaying fault information to assist maintenance personnel.

◆ Scans and identifies each specimen, automatically correcting errors. If a group of specimens is not placed in order, the system automatically identifies the error and prompts the operator to correct it and continue testing.

◆ Accuracy: Class 0.5.

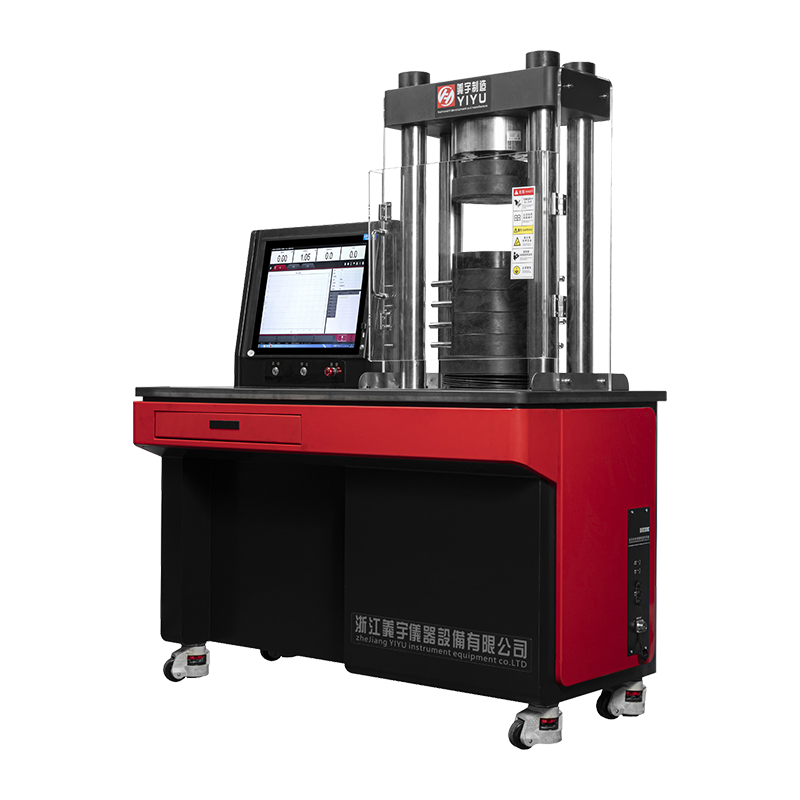

◆ Equipped with an automatically opening and closing protective cover that operates in conjunction with the feed system.

◆ The press's pressure-bearing space is rationally designed for easy verification and calibration. ◆ Control multiple presses with a single software suite, controller, and oil source cabinet.

◆ The press control software and master control software are integrated.

◆ The press features energy efficiency, quiet operation, fast movement, and precise control: operating noise levels are no higher than 40dB(A), and the hydraulic cylinder can move at speeds up to 300mm/min.

◆ Digital twin technology is used to link software animations with real-time robot movements, facilitating observation and interpretation.