What are the main components of a pressure testing machine?

The basic structure of a pressure testing machine

A complete and high-performance pressure testing machine usually consists of the following key modules:

1. Pressure Loading System

The pressure loading system is the "power heart" of the whole machine, responsible for applying liquid or gas medium to the object being tested, thereby simulating the pressure bearing conditions in its actual working environment. According to different application scenarios, the loading method can be divided into hydraulic (such as using hydraulic oil), air pressure (such as using compressed air or nitrogen) or mixed drive mode. The loading system independently developed by Yiyu Instrument has the characteristics of fast response, strong stability, and good sealing, and is widely used in various standard and non-standard test tasks.

2. Pressure Control and Regulation Unit

In order to achieve high-precision pressure control, modern pressure testing machines are mostly equipped with closed-loop control systems, integrated with high-sensitivity pressure sensors and proportional control valves, which can accurately control the pressure rise rate, holding time and drop process. Yiyu Instrument adopts a multi-level PID control algorithm to ensure that the test pressure is stable and shock-free, and to maximize the safety and repeatability of the test.

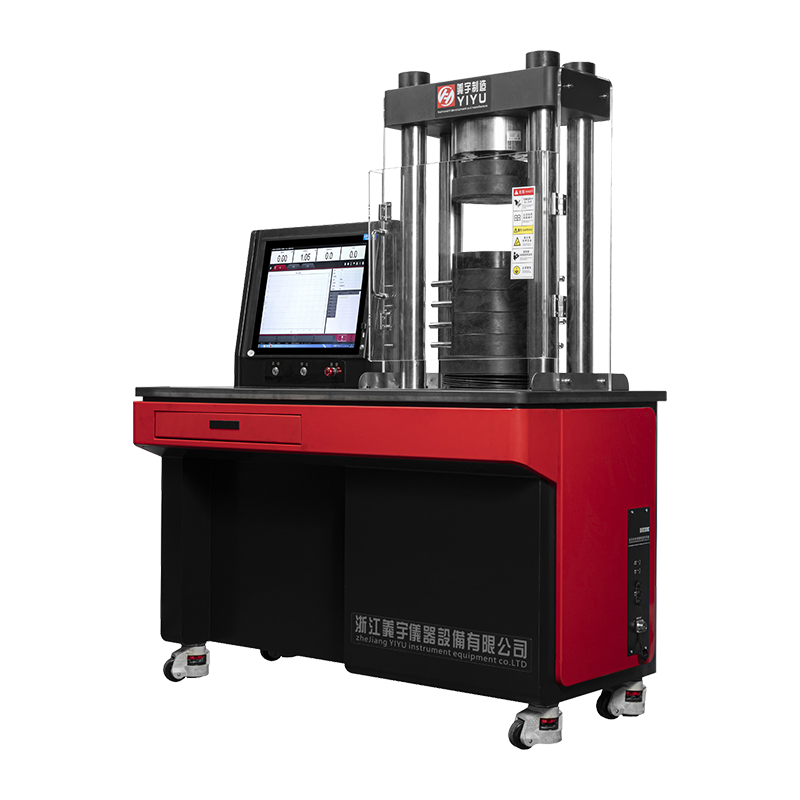

3. Test Chamber or Clamping Fixture

The test chamber is used to hold the object to be tested (such as pipes, containers, valves, etc.) and provide a sealed space to carry the internal pressure. According to the size, shape and material of different test objects, Zhejiang Yiyu Instrument Equipment Co., Ltd. supports a variety of fixture customization solutions, and uses aviation-grade aluminum and stainless steel to ensure the corrosion resistance and structural strength of the equipment, which is particularly suitable for the testing needs of workpieces with complex geometric structures.

4. Data Acquisition & Analysis System

An efficient data acquisition system is the key to achieving automated testing. Modern pressure testing machines generally use high-speed A/D converters to collect and record signals such as pressure, temperature, time, and flow in real time. Yiyu pressure testing machines are equipped with self-developed data management software, which not only supports graphical display and historical curve playback, but also can export data to Excel, PDF and other formats, which is convenient for users to trace quality and connect with third-party inspections.

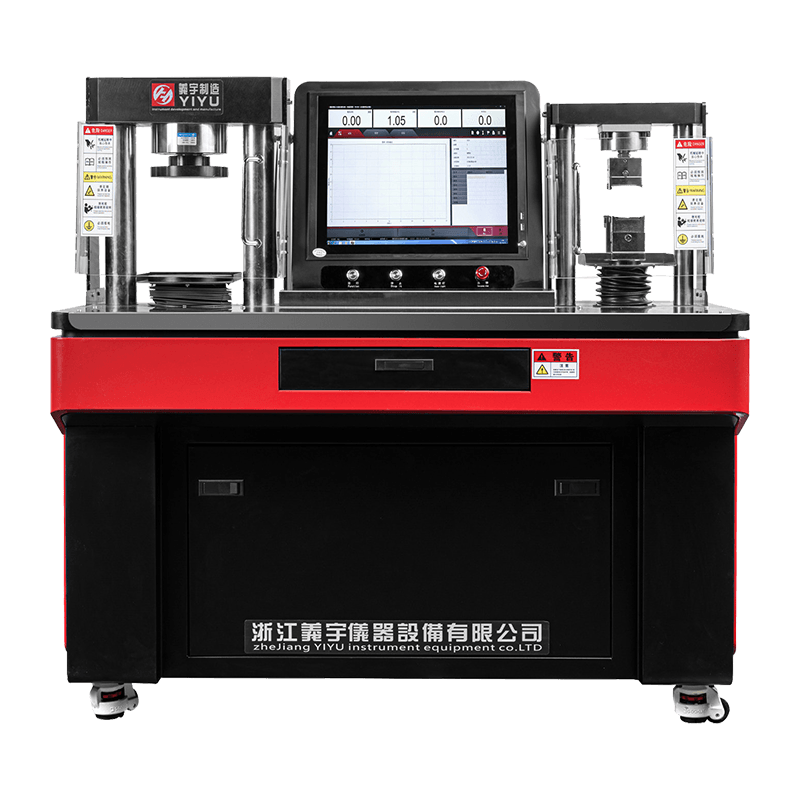

5. Control interface (Human-Machine Interface, HMI)

The user interface is directly related to the convenience of operation and test efficiency. Zhejiang Yiyu Instrument Equipment Co., Ltd. introduced a dual control mode of touch screen + physical button in the control interface design, which not only adapts to the development trend of intelligence, but also retains the reliability of industrial operation. The interface supports multi-language switching, multi-user authority management and remote control, providing customized experience for global customers.

6. Safety Protection System

Since the pressure testing machine involves high pressure, high temperature and other working conditions, it must be equipped with a complete safety protection mechanism. Including but not limited to: automatic unloading of overpressure, emergency stop button, explosion-proof pressure relief port, overload alarm, etc. Yiyu pressure testing machines are designed and produced in accordance with national standards and EU CE certification requirements to maximize the safety of operators and experimental environments.

How often is the pressure testing machine calibrated?

Why does the pressure testing machine need to be calibrated regularly?

The essence of calibration is to confirm the accuracy of the equipment measurement results by comparing with standard measuring tools or reference devices, and to make necessary corrections to system errors. For pressure testing machines, the core indicator is the accuracy of the "pressure value". Any slight deviation may lead to product quality risks, misjudgment of safety tests, and even legal liability or quality disputes.

For example, if the equipment has not been calibrated for a long time, resulting in a low actual pressure value, it may cause the tested parts to burst or leak in actual applications, thus posing a serious hidden danger to the safety performance of the terminal product. Therefore, establishing a scientific calibration cycle and process not only reflects the company's emphasis on quality control, but is also an important guarantee for the product to successfully pass third-party certification and market inspection.

Standard calibration cycle of pressure testing machine

According to the recommendations of the International Organization for Standardization (ISO), national metrology regulations and relevant industry specifications (such as "JJG 875-2005 Pressure Measuring Instrument Verification Procedure"), the calibration cycle of the pressure testing machine is usually once a year. The specific time interval can also be adjusted appropriately according to the following factors:

Frequency of use: It is recommended that equipment with high frequency and heavy load testing be calibrated every 6-9 months;

Working environment: High temperature, high humidity, dusty or frequent vibration environments will accelerate sensor aging, and the calibration cycle needs to be shortened;

Historical error records: If the equipment has a large error during calibration, periodic testing needs to be strengthened;

Customer quality management system requirements: Some companies or industries (such as aviation, military industry, and medicine) have more stringent internal calibration standards.

As a professional instrument manufacturer, Zhejiang Yiyu Instrument Equipment Co., Ltd. recommends that customers perform full-function calibration of pressure testing machines at least once every 12 months in accordance with national standards and their own management system requirements to ensure that test data is always under control.

Yiyu pressure testing machine Calibration Service System

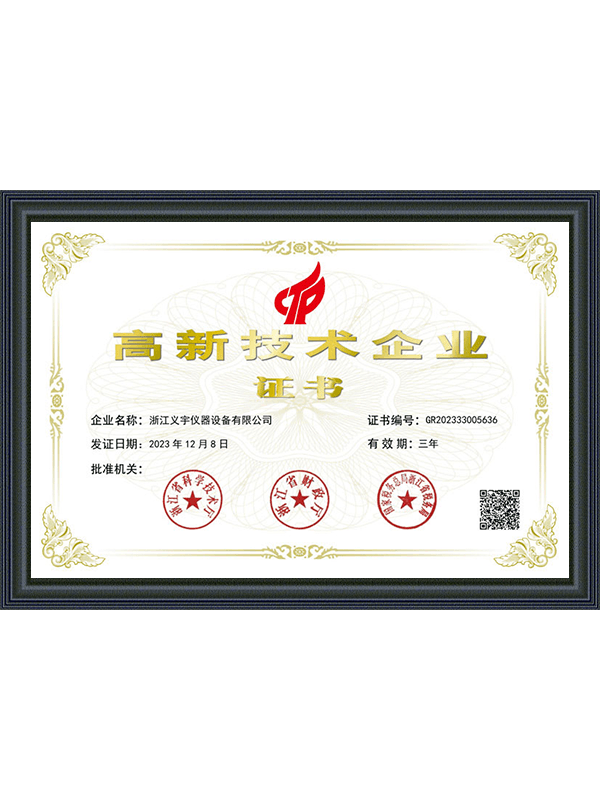

As a national high-tech enterprise located in Lianxing Village, Dongguan Street, Shangyu District, Shaoxing City, Zhejiang Province, Zhejiang Yiyu Instrument Equipment Co., Ltd. not only focuses on the research and development and manufacturing of material mechanical properties testing equipment, but also has established a complete system for after-sales service and equipment maintenance.

At present, the company has provided thousands of customers across the country and multiple overseas projects, including:

Factory calibration certificate;

Third-party authoritative calibration docking (such as the National Institute of Metrology or laboratories with CMA qualifications);

Remote assistance and localized calibration reminder services;

Traceable calibration record archiving mechanism.

In addition, Yiyu provides personalized calibration solution design, and can provide calibration tooling, mobile calibration instruments and on-site debugging services according to customer working conditions, greatly reducing customer equipment downtime and improving production and testing efficiency.

Common calibration problems and countermeasures

Q: What do I need to prepare before calibration?

A: Please make sure that the device is powered off, the test port is clean and free of impurities, and providing the specifications of the tested product and historical test data can help improve calibration efficiency.

Q: Is non-original calibration valid?

A: As long as the calibration unit has the corresponding qualifications (such as CMA, CNAS), its calibration results are valid in law and quality certification. However, Yiyu recommends giving priority to the original manufacturer or its authorized service provider to ensure the compatibility of the equipment system and the reliability of the results.

Q: Can the equipment life be extended after calibration?

A: Although calibration itself does not directly extend the life, it can prevent potential failures and reduce the frequency of maintenance by timely discovering system deviations and component aging, indirectly extending the life cycle of the equipment.

What is the operating process of the pressure testing machine?

Preparation phase: the premise of ensuring safety and test accuracy

Before any pressure test begins, the operator must make the following preparations:

1. Check the equipment status

Confirm that the equipment power supply is normal, the air pressure/hydraulic system has no leaks, and the control system starts without fault alarms. The pressure testing machine provided by Yiyu Instrument has an automatic self-test function. When it starts, it will perform a system-level inspection of modules such as sensors, solenoid valves, and control panels, which greatly improves the safety of the test.

2. Confirm the test medium

Select the appropriate medium (such as water, gas, oil or mixed fluid) according to the characteristics of the sample to be tested. Yiyu test equipment is compatible with a variety of media, and users can quickly switch according to the test standards.

3. Install the sample to be tested

Firmly install the workpiece to be tested (such as pipes, containers, valves, etc.) in the test chamber or special fixture. The seal must be intact and the interface must be tight to prevent pressure relief or displacement during the test.

4. Set the test parameters

Set relevant parameters in the touch interface or industrial control system, including test pressure, pressure holding time, pressure rise rate, pressure relief rate, etc. The intelligent control system configured by Yiyu Instrument supports preset parameter templates, which is suitable for repetitive test items and improves operational efficiency.

Loading stage: Apply pressure accurately and safely

Once the preparation work is completed, the equipment can be started to enter the pressure loading process:

1. Start the loading system

According to the preset pressure curve, the control system starts to load automatically. During the loading process, the system will monitor the current pressure in real time and display it on the operation interface, and the error is controlled within ±0.1%.

2. Reaching the target pressure

After the pressure rises steadily to the set value, the system automatically enters the "pressure holding" state. The stability of this stage directly reflects the accuracy of the test equipment and the sealing ability of the system. Yiyu pressure testing machine is equipped with high-precision proportional valves and closed-loop regulation systems to ensure minimal pressure fluctuations, suitable for industries such as aerospace and nuclear energy that require extremely high test accuracy.

3. Automatic data recording

During the entire loading and pressure holding stage, test data (including pressure value, time, temperature, etc.) will be collected and saved in real time to facilitate subsequent analysis and report generation. Yiyu's self-developed data acquisition system supports multi-channel input, multi-format export, and graphical report printing.

Pressure relief and end stage: ensuring the safety of operators and equipment

1. Automatic pressure relief

After the test is completed, the system will automatically and slowly relieve the pressure according to the set program to prevent damage to the equipment or workpiece due to a sudden drop in pressure.

2. Removal of test piece

After confirming that the pressure is zero and completely removed, the operator can remove the tested sample and check for deformation, rupture or other structural changes.

3. Data output and report generation

After the test is completed, the system will automatically generate a complete test report based on the collected data, including test parameters, pressure curves, abnormal records, etc. The Yiyu system supports Chinese and English report templates to meet domestic and foreign certification requirements.