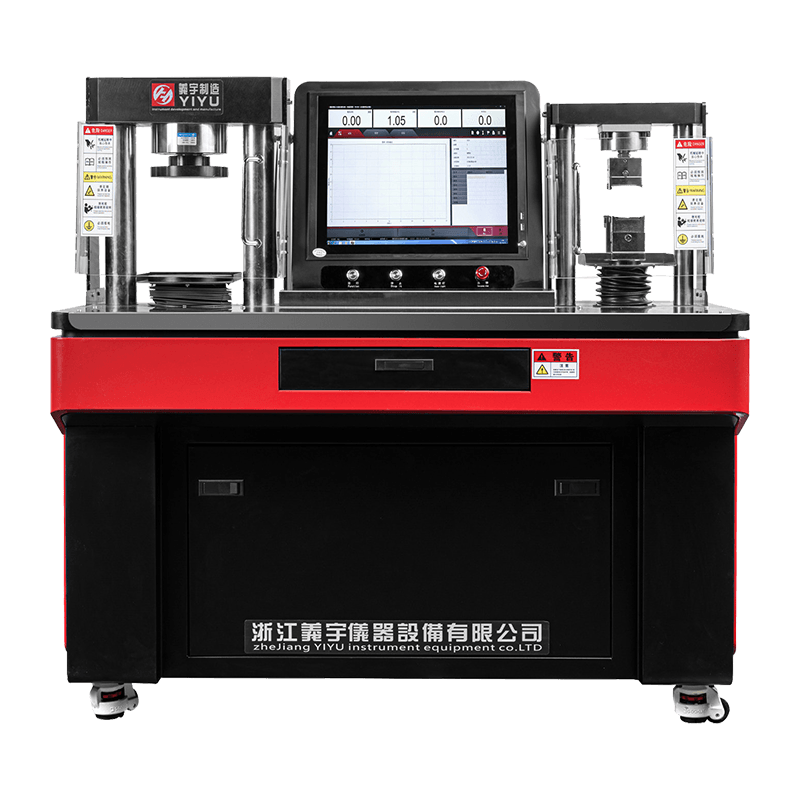

Function Overview:

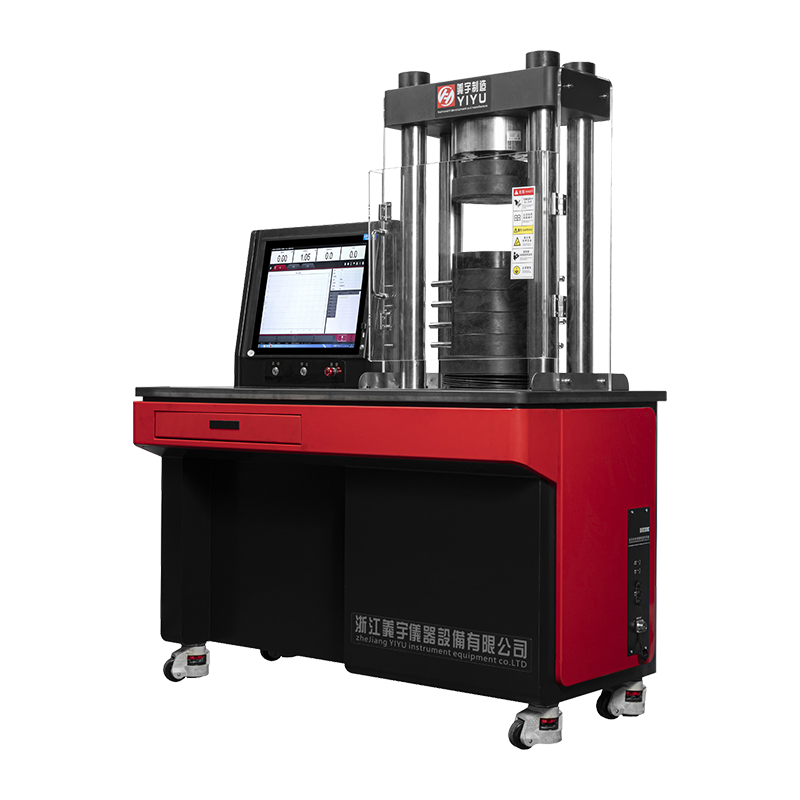

The specialized testing machine for steel pipe scaffold fasteners is a specialized testing machine used to test the mechanical properties of steel pipe scaffold fasteners.

The host adopts high-strength column support and high-precision ball screw transmission

Motion, with high rigidity and good linear motion characteristics.

The accompanying FastTest V1.2 software is simple, fast, and convenient, making the user testing process easier.

1. Ball screws and heavy-duty bearings ensure long-term operation of the equipment, accurate test results, and good repeatability

2. Multi column guidance increases the lateral rigidity of the equipment, ensuring stable linear motion of the crossbeam, and the self-lubricating structure is maintenance free

3. 14 sets of fixtures meet 17 test items for three major types of steel pipe scaffolding components: steel pipe scaffolding fasteners, socket type disc fasteners, and bowl type steel pipe scaffolding components

4. Servo motor provides guarantee for the stability of the experiment

5. A fully digital closed-loop control system that can achieve constant velocity deformation, constant velocity loading, constant velocity displacement, and multiple cyclic functions

6. Synchronous belt drive provides good reliability, minimal maintenance, and excellent force/speed characteristics

7. Adjust the lifting feet for easy entry and positioning